CBS 60 Minutes - See the interview with our CEO, Dr. Duane Priddy

Polypropylene Mesh Failure - Plastic Expert Dr. Duane Priddy Sr. - CBS News / 60 Minutes Report

Engage with our team of

50+ globally recognized experts

We have expertise across multiple industries, all types of pipes, with residential and commercial implementations.

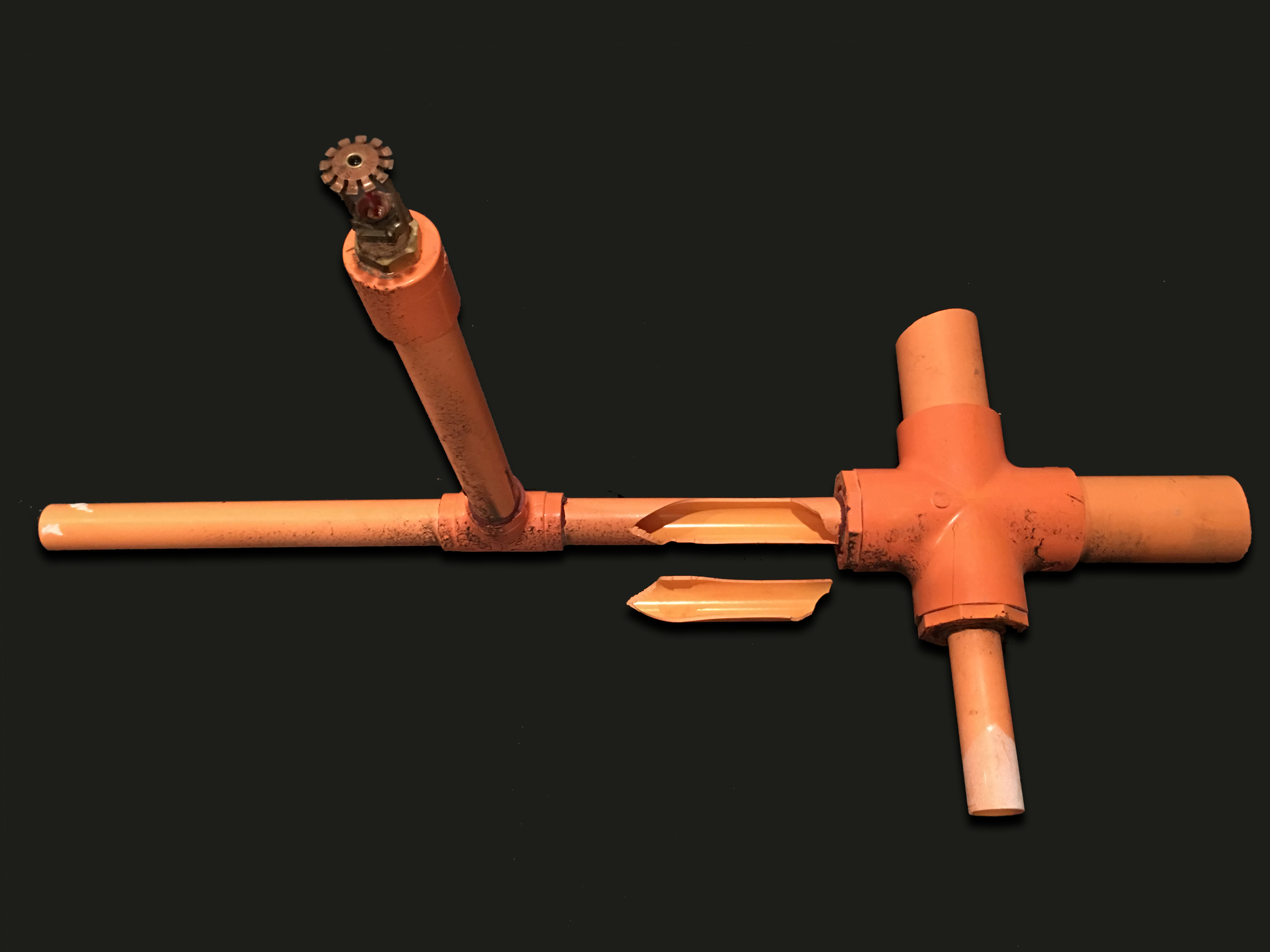

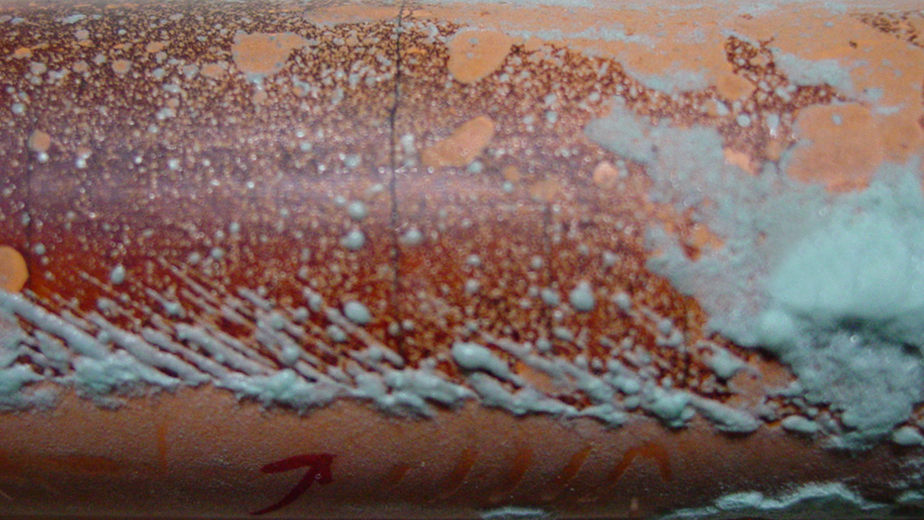

CPVC

CPVC piping is not chemically compatible with many chemicals, especially esters and amines. CPVC pipe failure, CPVC joint failure, CPVC pipe leaks, CPVC pipe defects, and CPVC joint failures can result simply by exposure of the piping to many different types of common products including hand lotion, fire caulk, electrical wire, computer network cables, solder flux, spray foam insulation, impure glycerin antifreeze, and pipe thread sealant paste. Certain steel pipes connected to the CPVC can also contaminate the CPVC with incompatible chemicals. We are CPVC pipe experts and CPVC fire sprinkler experts including CPVC remediation and issues involving CPVC contamination and CPVC antifreeze contamination issues. We were the first to determine that Allied ABF steel pipe is incompatible with CPVC. We do CPVC pipe inspection, CPVC pipe analysis, and CPVC chemical compatibility testing.

PVC

PVC failures and PVC pipe leaks occur for a number of reasons but most often the root cause of PVC pipe failures are PVC pipe defects and PVC installation defects. We do PVC pipe inspection and PVC pipe inspection. Whether you use PVC piping for potable water service, for hydronic cooling, for drains, or for sewer service, our PVC pipe experts and PVC pipe consultants can determine the root cause of PVC pipe failure. Our PVC pipe testing will determine if the pipe was defectively manufactured and whether the PVC C-900 pipe complies with ASTM and AWWA standards. We perform ASTM D2152 and ISO18373 testing to determine if the pipe was manufactured properly to withstand high pressure.

PEX

We are plastic pipe experts on all types of plastic pipe failures. including CPVC, PVC, and PEX. If you have a plastic pipe leak involving a plastic pipe defect, we can help. We do plastic pipe analysis and plastic pipe inspection. PEX piping can fail due defective manufacture or defective installation including inadequate minimum bend radii and pipe kinking. Extreme bends cause stress on piping and oxidative degradation. PEX failure, PEX pipe failures and PEX pipe leaks cause millions of dollars of property damage every year. The PEX piping shown in the above photograph was removed from homes in a subdivision. All of the PEX piping was replaced because of defective PEX. We are PEX experts and PEX consultants.